The authentic history of Sandblasting

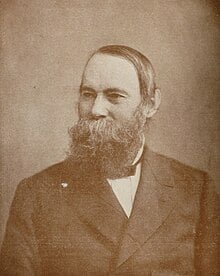

Please remember Benjamin Chew Tilghman the next time that you need something sandblasting.

Benjamin Chew Tilghman (October 26, 1821 — July 3, 1901) was an American soldier and inventor. He is best known as the inventor of the process of sandblasting.

Around 1870, he invented the sandblasting process and filed a patent for it in the US (US patent 108,408.), detailing many of the applications for which this technique is uniquely suited, such as sharpening files, engraving bottles, cleaning boilers or bringing out the grain in wood. Later that year a patent was issued in the UK.

In 1871, at the 40th Exhibition of the American institute of the city of New York, he was awarded the institute’s Great Medal of Honor for his invention; shortly after, he was also awarded the Elliot Cresson Medal by the Franklin Institute.

He refined the technique for various purposes, and in 1877 took out a patent (US patent 252,279) for sharpening files, which he marketed as “Liquid Grindstone”.

Legend has it that Tilghman had seen the effect of wind-blown sand on windows in the desert while a general in the army, and that this was the basis of his sandblasting invention.

One hundred and fifty four years later :-

The process hasn’t changed a great deal since then as it still involves throwing sand or a similar media at a surface to get it clean or alter its shape.

What has changed, are the machines that we use nowadays to let us prepare the surfaces in the best way for the job that we are doing at that moment.

The main component in our workshop is the compressor which produces a volume of 400 cubic feet per minute of compressed air at computer controlled pressures between 73 and 160 PSI. The volume and pressure can be drastically reduced further by various valves when we need to do more delicate work. The airflow can be further modified by the size of the blast nozzle.

The compressed air is then routed through a 600 CFM refrigerated dryer which removes all of the moisture that is present in the air to ensure that any metal that we are cleaning is in perfect condition.

Sandblasting process

The actual method of sandblasting sorts the men out from the boys when it comes to thinner metal that can be easily distorted ( such as car bodies and panels).We have over the years refined our skills so that we know the best pressures and angles to use on work like this. Even on thin Aluminium panels we can remove the paint one layer at a time and leave the surface in better condition than when it was manufactured.

We are not trying to beat the record on a time basis , but to ensure that the client is happy with the end result.